The global polybutadiene market size stood at a value of USD 7.61 billion in 2024 and is expected to grow at a Compound Annual Growth Rate (CAGR) of 4.20% in the forecast period of 2025-2034, reaching a value of USD 11.48 billion by 2034. Polybutadiene, a synthetic rubber made from the polymerization of butadiene, plays a crucial role in the production of tires, industrial products, consumer goods, and more. It is widely valued for its excellent performance characteristics, such as durability, wear resistance, and elasticity. The growing demand for polybutadiene is largely driven by the increasing use of tires, the automotive industry, and the expanding demand for high-performance rubber materials across various industrial sectors. This essay delves into the factors driving market growth, the latest trends, regional dynamics, challenges faced by the industry, and the outlook for the polybutadiene market in the coming years.

Overview of Polybutadiene

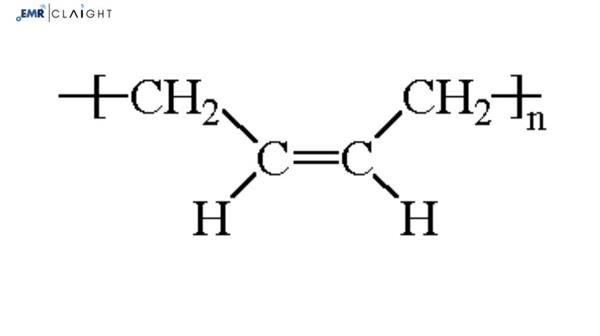

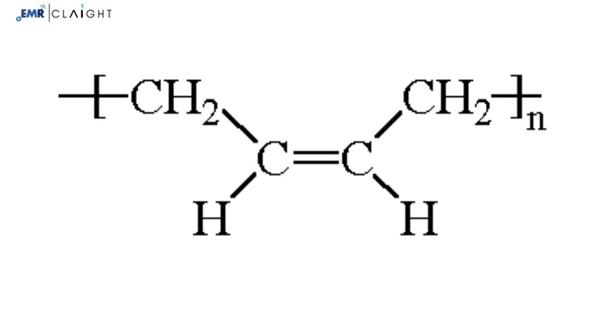

Polybutadiene is a type of synthetic rubber derived from the polymerization of 1,3-butadiene, a monomer that is produced through various processes, such as petroleum refining or natural gas processing. Polybutadiene's key characteristics, including low rolling resistance, durability, abrasion resistance, and high tensile strength, make it a material of choice for numerous applications. Most notably, it is widely used in the tire industry, where it contributes to enhanced fuel efficiency, safety, and longevity of tires. Beyond tires, polybutadiene finds its place in the production of footwear, seals, gaskets, and industrial rubber goods, as well as thermoplastic elastomers (TPEs), which combine the properties of plastics and elastomers for a range of applications.

Polybutadiene rubber exists in various grades, such as high-cis polybutadiene, low-cis polybutadiene, and trans-polybutadiene. The high-cis version is particularly preferred in tire manufacturing due to its superior wet traction and wear resistance. Polybutadiene's flexibility and high resilience make it suitable for applications where high performance, weather resistance, and cost-effectiveness are required.

Get a Free Copy of Our Detailed Report

Market Drivers: Factors Influencing the Growth of Polybutadiene

The polybutadiene market is growing steadily due to several influential factors. The primary driver is the booming automotive industry, which continues to rely heavily on polybutadiene in the production of tires. Polybutadiene enhances tire performance in multiple ways. It improves durability, reduces rolling resistance, and increases traction, thereby enhancing fuel efficiency and road safety. With increasing automotive production globally, the demand for polybutadiene is set to rise. The increasing adoption of electric vehicles (EVs) and hybrid vehicles is also expected to spur growth, as these vehicles require tires that provide higher performance in terms of rolling resistance and durability.

One of the critical factors contributing to the growing demand for polybutadiene is the emphasis on sustainable and energy-efficient solutions in the automotive sector. Tires made from polybutadiene are designed to have low rolling resistance, which improves fuel efficiency and reduces carbon emissions. This is especially important as governments and businesses worldwide focus on reducing their environmental footprint and adhering to stricter environmental regulations. The demand for eco-friendly solutions, including energy-efficient tires, is boosting the adoption of polybutadiene in tire manufacturing.

Another key driver is the rising demand for synthetic rubber in the industrial and consumer goods sectors. Polybutadiene's versatility, combined with its superior mechanical properties, makes it a preferred choice for producing various products, such as industrial seals, gaskets, hoses, footwear, and coatings. The material's high resilience and resistance to wear make it particularly popular in applications where longevity and performance are essential. As industrial and consumer goods sectors continue to expand, the demand for polybutadiene is likely to increase.

Furthermore, technological advancements in polybutadiene production, such as more efficient polymerization methods and the development of new grades of polybutadiene, are fueling the market's growth. These innovations not only improve the quality of the material but also reduce production costs, making polybutadiene more accessible for manufacturers across industries.

Emerging Trends in the Polybutadiene Market

Several trends are emerging within the polybutadiene market that could significantly impact its future. One of the most significant trends is the growing focus on sustainable materials. As the world becomes more environmentally conscious, there is a noticeable shift towards bio-based and eco-friendly alternatives to traditional petrochemical-based materials. The production of bio-based polybutadiene, derived from renewable sources such as bioethanol or biomass, is gaining attention. While still in its early stages, bio-based polybutadiene offers the potential to reduce the carbon footprint of synthetic rubber and contribute to the global push for sustainability. As research in this area progresses, bio-based polybutadiene could see wider adoption in the coming years.

Another emerging trend is the increasing use of polybutadiene in thermoplastic elastomers (TPEs). TPEs combine the best features of plastics and rubber, offering flexibility, durability, and ease of processing. These materials are widely used in the automotive, medical, and consumer goods industries, particularly for manufacturing seals, gaskets, and soft-touch components. Polybutadiene plays a crucial role in the production of TPEs, making it an essential material for these expanding industries.

The demand for polybutadiene in high-performance tires is also increasing, driven by advancements in tire technology and the growing emphasis on fuel efficiency and safety. As the automotive industry continues to innovate, polybutadiene's role in enhancing tire performance, such as improving wet traction, reducing rolling resistance, and enhancing wear resistance, will be critical in meeting the ever-growing consumer demand for high-performance tires.

Challenges in the Polybutadiene Market

Despite its promising growth trajectory, the polybutadiene market faces several challenges that could impact its future development. One of the main challenges is the volatility of raw material prices, particularly the cost of butadiene. Butadiene is derived from crude oil and natural gas, and fluctuations in global oil prices can lead to significant variations in the cost of polybutadiene production. This volatility can make it difficult for manufacturers to maintain consistent production costs, potentially affecting the overall price stability of polybutadiene.

Another challenge is the increasing competition from alternative materials. While polybutadiene is widely used in tire production, it faces competition from other types of synthetic rubber, such as styrene-butadiene rubber (SBR), which offer similar performance properties. The availability of cheaper alternatives could limit the market share of polybutadiene, particularly in regions where cost-sensitive applications are prevalent.

Additionally, the environmental impact of polybutadiene production is an area of concern. Traditional polybutadiene production methods are energy-intensive and can generate significant greenhouse gas emissions. As governments and industries increasingly prioritize sustainability, there may be greater pressure on polybutadiene producers to adopt cleaner production methods and reduce their carbon footprint. Companies that fail to adapt to these environmental concerns may face regulatory challenges or consumer backlash.

Regional Insights: North America, Europe, Asia Pacific, and Rest of the World

The polybutadiene market is geographically diverse, with varying growth trends across different regions. North America and Europe are established markets for polybutadiene, driven by well-developed automotive industries and the increasing demand for energy-efficient and high-performance tires. The focus on sustainability and green technologies in these regions is driving the adoption of polybutadiene in various applications, including automotive tires and thermoplastic elastomers.

Asia Pacific is expected to experience the highest growth rate in the polybutadiene market. Rapid industrialization, increasing automotive production, and expanding consumer goods sectors in countries like China, India, and Japan are driving the demand for polybutadiene in the region. As automotive manufacturing and infrastructure development continue to surge in Asia Pacific, the demand for synthetic rubber and high-performance materials, including polybutadiene, is expected to rise.

In Latin America and the Middle East, the polybutadiene market is seeing steady growth as infrastructure development and industrialization expand. As these regions experience greater economic development and urbanization, the demand for polybutadiene-based materials is expected to rise, particularly in the automotive and industrial sectors.

Future Outlook of the Polybutadiene Market

The future outlook of the polybutadiene market appears promising, with continued growth expected throughout the forecast period. The automotive industry remains the dominant consumer of polybutadiene, and the increasing demand for tires with enhanced fuel efficiency, durability, and safety will drive continued market expansion. Furthermore, the rising demand for electric vehicles and hybrid vehicles, which require specialized tires, will likely increase the need for polybutadiene.

Advancements in sustainable production methods, such as bio-based polybutadiene, and the growing adoption of polybutadiene in thermoplastic elastomers will open new opportunities for the market. As industries across the globe continue to prioritize sustainability and energy efficiency, polybutadiene will play an integral role in meeting these demands.

The polybutadiene market is set to experience steady growth, driven by the automotive sector, technological innovations, and the increasing demand for high-performance materials. While challenges such as raw material price volatility and competition from alternative materials exist, the market's overall outlook remains positive. Polybutadiene's unique properties, such as durability, wear resistance, and flexibility, ensure that it will continue to play a critical role in various industrial applications, making it a vital material in the years to come.